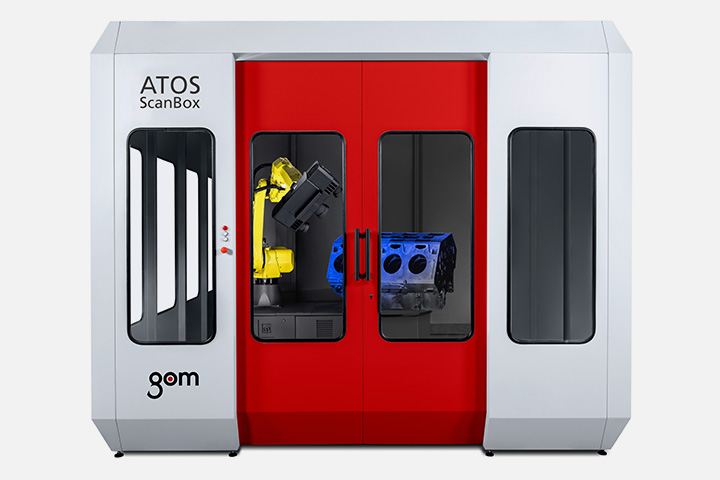

High performance in compact size

- Measurement and inspection of parts up to 2000 mm in size, such as automotive interior components

- Applications include direct use in harsh environments, such as foundries and forging applications

ATOS ScanBox Series 5 optimizes your series inspection and supports you in checking your production processes. Standardized and automated procedures increase throughput of parts and reduce scrap. The ATOS ScanBox 5108 and ATOS ScanBox 5120 systems allow for high process reliability during operation thanks to trend analyses in real time. Changes within the production can thus be identified quickly.

Customized for Airfoil Inspections

ATOS ScanBox 5108 is predestined for inspecting airfoils. Developed for gas turbine industries, ATOS 5 for Airfoil with its optimized working distance and measuring areas from 100 x 70 mm² delivers high-precision 3D data of the smallest details. You can measure a complete blisk in less than an hour. A turbine blade is inspected within a few minutes.

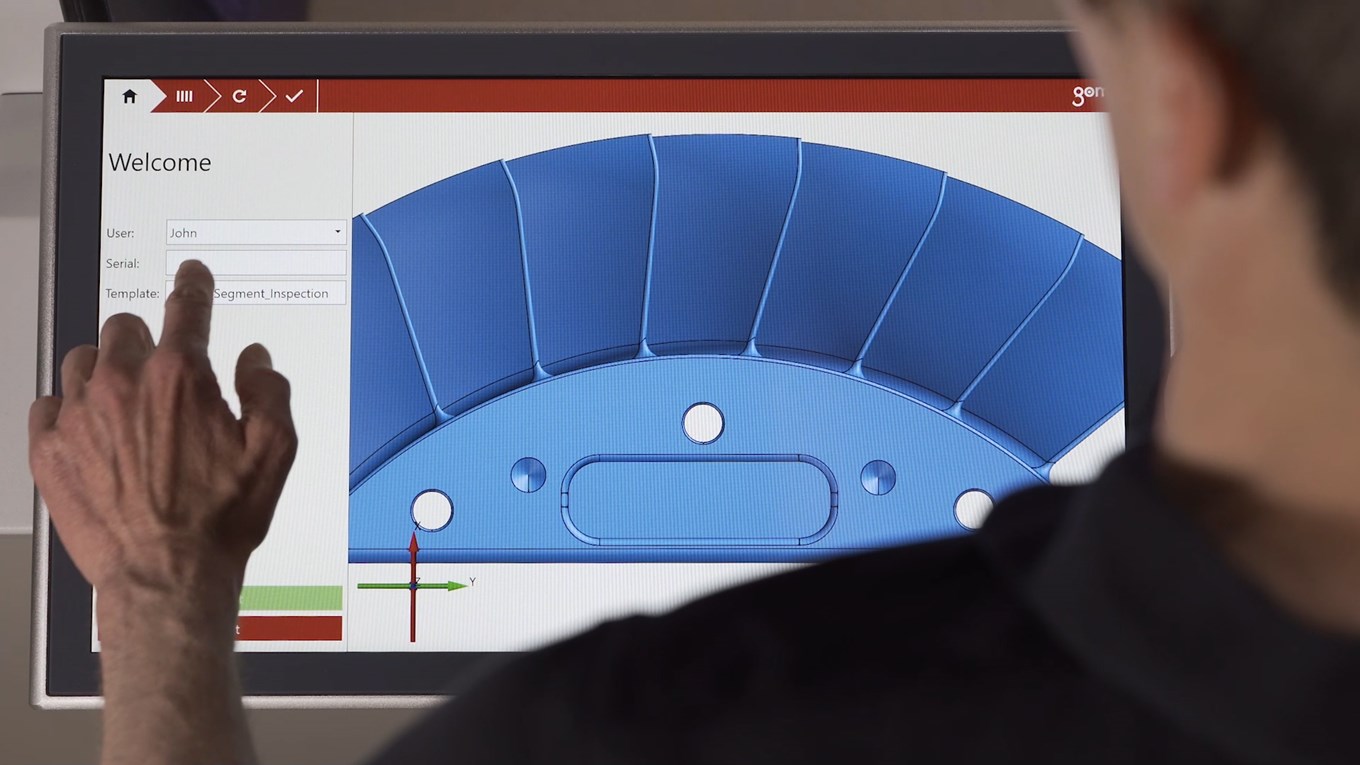

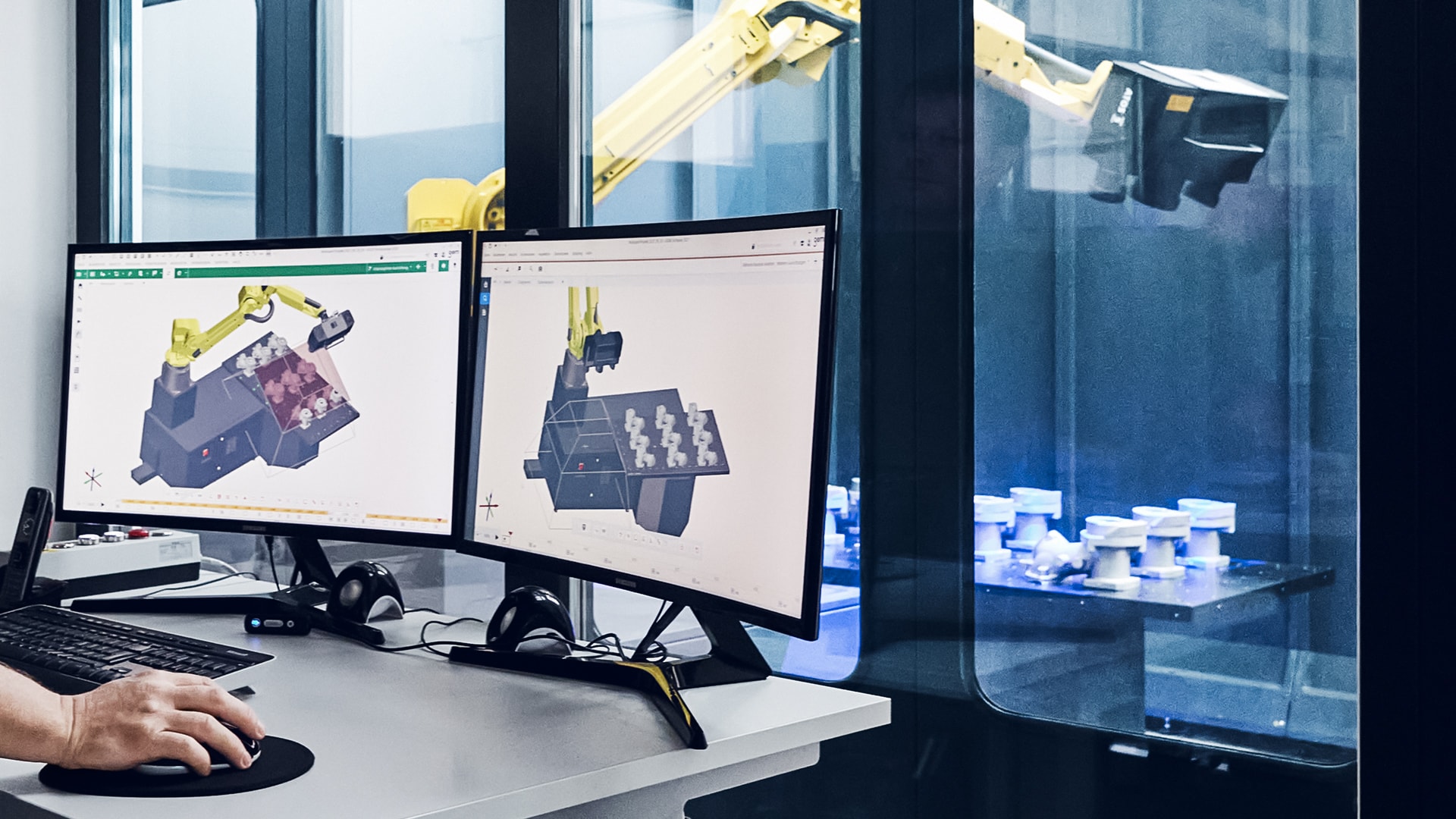

ATOS ScanBox Series 5 is developed for serial measurements and is often directly used in the production environment. Measuring procedures are automated and the reproducibility of 3D measurement data of identical parts is ensured. You create the measuring programs for inspection in the virtual measuring room (VMR) of the GOM Inspect Pro software. The robot is fully controlled by the software and successively moves along the measurement positions. Changes to the data status of the CAD or the inspection plan can be quickly updated by the parametric structure of the software. In the company, workers can operate the system.

Production-Integrated Inspection

A significant advantage of ATOS ScanBox Series 5 is its flexibility – retooling and integration into new production processes is possible within one day. The system can be placed either close to the production line or directly within the production. This way, you do not have to transport parts to remote measuring rooms. Reaction times during the check are reduced, as are correction loops in the production process. For even higher throughput, ATOS ScanBox 5108 can be expanded with an automated handling system and a programmable logic controller. The system enables unmanned loading and unloading as well as automated measurements and inspections in line with an inspection plan.

Virtual Measuring Room in GOM Inspect ProThe virtual measuring room (VMR) is the central control station and measurement planning software for all elements of the ATOS measuring cells. In the VMR, the real environment, i.e., robots, sensors and parts in the measuring cell, is functionally simulated in a simulation. The programming includes the kinematics, the robot paths, the part fixture and the measurement plan. Thanks to the VMR, the user can work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.